Markets

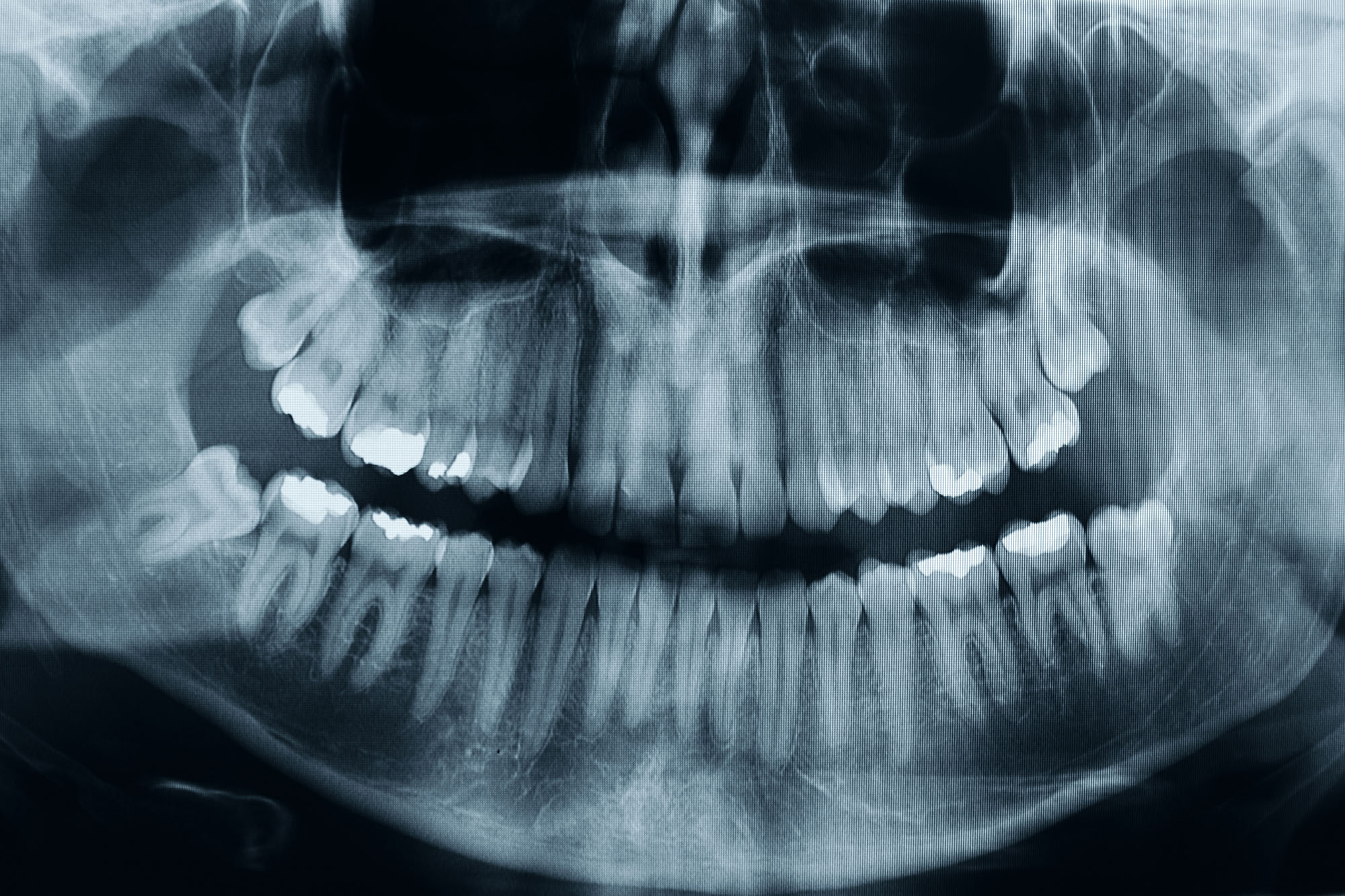

Dental

Our nanoparticles can be incorporated in dental composites, adhesives, coatings and other materials, as radiopacifiers, refractive index and shrinkage modulators, remineralizing and anti-bacterial agents, mechanical properties enhancers.

Fine ceramics

Nanoparticles with controlled morphology and surface activity can be used to tune the microstructure of ceramics and composites, obtaining smaller grain sizes at lower sintering temperatures and allowing the design of novel microstructures in dense or nano-porous materials. The resulting mechanical and optical properties can be significantly improved.

Optics / photonics

Nanoparticles can be incorporated into optical materials to modulate refractive index, convert, filter or scatter UV, visible and IR radiations.

Solid-state lighting

Nanomaterials can improve the output of LEDs by increasing the efficiency of light extraction and modifying the way light is delivered

Displays

Nanoparticles can increase brightness and quality of vision, as well as reduce power consumption to improve the display efficiency.

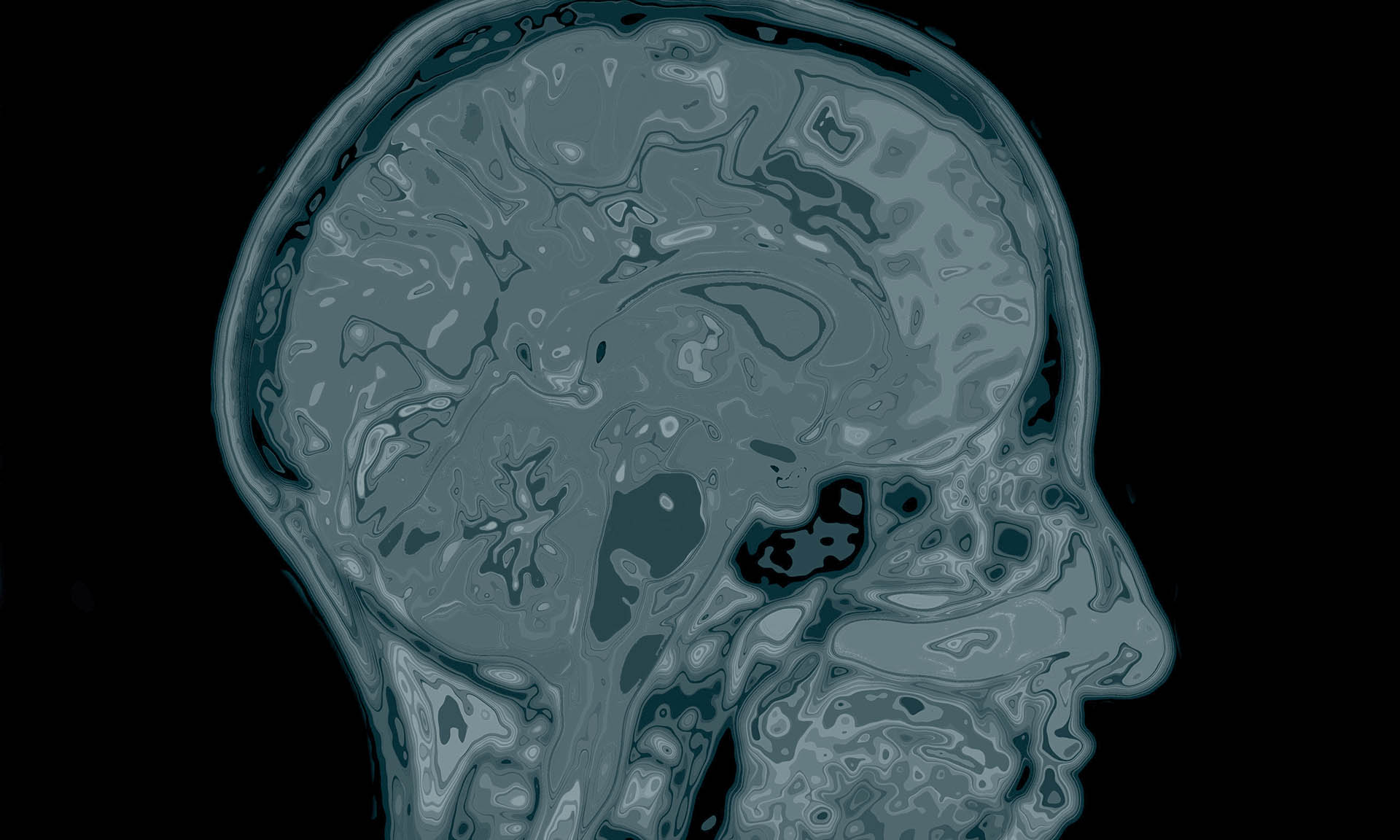

Biomedical applications

Mathym nanoparticles allow the development of novel medical imagery techniques, improve bioactivity, and rend implants visible on radiographies

Semiconductor manufacturing

Our nanoparticles can be used as abrasives in chemical-mechanical polishing slurries to ensure defect-free performance at advanced nodes

Environment

Main applications include nanoporous layers in ultrafiltration/nanofiltration ceramic membranes for gas separation, water decontamination, food processing, chemical and pharmaceutical manufacturing

Energy

Nanoparticles of controlled size and composition can be beneficial in all the applications where a high surface activity and the ability of creating high-resolution structured surfaces are crucial aspects for energy transfer, including fuel cells, batteries, catalysis and hydrogen production

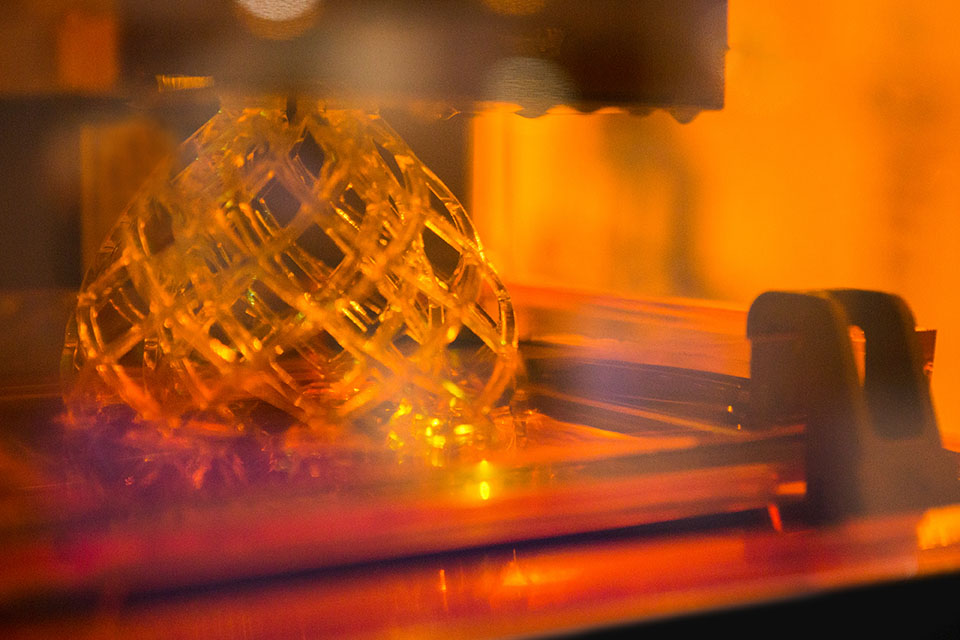

2D/3D Printing

The absence of agglomerates and optimal compatibility of our nanomaterial dispersions allow them to be used as feedstock in several 3D printing technologies, especially when high resolution and transparency are at stake.

These technologies include:

- Stereolithography

- Direct-Light Processing

- 2-Photons Lithography

- Inkjet Printing

- Nanoimprint lithography

Adhesives and sealants

The performance of adhesives and sealants can be improved in terms of refractive index matching, radiopacity, reduced shrinkage, mechanical properties